Adequate rigidity - no excessive elastic deformation;

Sufficient stability - not to collapse due to sudden changes in the form of equilibrium;

The aluminum alloy truss has sufficient strength - no fracture or plastic deformation;

The product also has good dynamic characteristics - shock resistance and wind resistance.

The above content only mentioned a part, let's move on to other content!

Truss design requirements: to meet the requirements of the bar; Have good connectors, including rivets, pins, and welds.

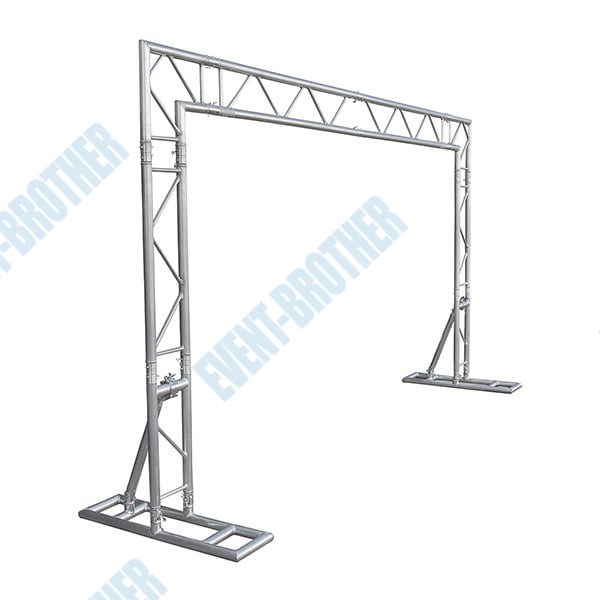

Aluminum alloy truss, a flat or spatial structure composed of straight rods, generally with triangular elements. Under the action of load, the truss members mainly bear axial tension or pressure, so that when the span is greater than the solid belly beam, it can fully use the strength of the material, save materials, reduce the weight, and increase the stiffness, which is suitable for bearing structures and high-rise structures with large spans, such as roof truss, bridge, transmission line tower, satellite tower, hydraulic gate, crane frame, etc. Commonly used are steel trusses, reinforced concrete trusses, prestressed concrete trusses, wood trusses, steel-wood composite trusses and steel-concrete composite trusses.

Trusses are divided into triangular trusses, trusses, polygonal trusses, parallel string trusses and hollow trusses according to their shapes. When selecting the truss form, the use, material, support mode and construction conditions of the truss should be considered comprehensively. Under the premise of meeting the requirements of use, minimize the material and labor used in manufacturing and installation.